This page is not a real translation but just an automatic translation generated by computer of the original article, written in French language! Its not good... but better than nothing!

This page is not a real translation but just an automatic translation generated by computer of the original article, written in French language! Its not good... but better than nothing!Want to help us do diffuse puerh tea culture in english, by providing a better (or corrected) translation?

Please contact us!

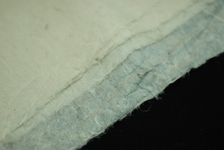

Various papers have over time summers used to pack fragile puerh (Pu Er tea) cakes. Also protect the wafers, these papers also allow flexible and porous exchange between tea and the ambient atmosphere, necessary for proper maturation of puerh (Pu Er tea) tea. The paper quality is thus crucial for proper conservation tea cake over the long term, prevent their degradation and enhance their maturation.

- 1. Packaging made of different papers more or less well preserved

- 2. Paper late 90s (Yi Da Red)

- 3. Paper craft thick

- 4. smooth paper for color printing

Among these papers is the traditional paper Dai, product and craftsmen from ancient times by Dai, one of the 26 ethnic groups inhabiting in Yunnan and particularly present in the producing regions such as puerh (Pu Er tea) Xishuangbanna Dai which are the majority, but also in Lincang and Pu'er.

Transmitted from mother to daughter for generations, this unique expertise has lasted until today, and Dai from different villages of Yunnan craftsmen continue to produce high quality paper, which is still used by some producers to pack their sharp puerh (Pu Er tea) cakes.

Particularly beautiful to the eye and soft to the touch it is a paper that is a pleasure to handle. Natural fibers that compose seem to dance on its surface, describe more or less tight curls and a canvas weave dense and irregular.

- 1. Paper crafts Dai

- 2. Paper crafts Dai (detail)

- 3. Paper craft Dai (fiber)

- 4. Paper crafts Dai (detail)

Handmade paper Dai also different remarkable properties: Produced from natural material it has a velvety feel very pleasant. But it also makes it particularly suitable for wrapping a loaf of tea for consumption, where we can deplore the use of certain industrial papers chlorine bleached and printed in full color from ink rich in heavy metals.

We also appreciate a quality paper Dai thickness and strength quite remarkable, allowing many packing and unpacking of the cake without the paper tearing. This paper also allows long-term storage of tea there or many modern industrial papers will degrade over the years. Despite this resistance has a good paper Dai also a very good porosity which allows the tea to breathe and age properly.

But there's also a piece of paper behind Dai charm of a craft product, made for generations with the same care in a family at the heart of the mountains of Yunnan, which gives the paper a particular value .

I therefore propose to go together in these two families, one in Xishuangbanna other in a village of Lincang to discover the secret of this valuable paper.

The making of a Dai paper sheet

Just as there there's Yunnan villages of potters, villages where weaves and dyes cotton, villages living tea, Dai families that produce paper are generally grouped in the same village. These villages, which are located in different areas populated by Dai are always near a river or stream, essential to the preparation of the paper. If these villages are not only life in general paper, almost all families will continue to produce traditional paper, as they always have, especially in periods of the year where agriculture requires less attention.

- 1.Drying paper in the streets of a village in Xishuangbanna Dai

- 3.Female Dai producing paper Linang

- 4.Woman Dai producing paper in Xishuangbanna

- 5.Female Dai producing paper in Xishuangbanna

Paper is traditionally crafted by women, especially seniors, who will then pass this knowledge to their daughters, but sometimes they are assisted by other members of the family especially for physical tasks like hammering.

Before producing paper must first make the wooden frames on which the leaves take shape. This is a simple wooden frame on which is stretched a cloth wide meshes. The nature of the fabric and the mesh size differ from one village to another mark differently the paper product.

- 1.freshly assembled wood frame

- 2.Canvas stretched over a frame

- 3.Pile of assembled frames

- 4.Female Dai returned to the river where she washed a stack frame

- 5.Woman Dai returned to the river where she washed a stack frame

As the majority of papers, paper Dai made from wood fibers. For this, the Dai traditionally use a wild tree called Gou ft (构 皮). Mulberry's family of Spain or paper mulberry, it is a tree whose bark is made of highly resistant fiber, allowing the production of a high quality paper. From Asia (not Spain) this tree is predominantly present in the south of China and other countries in South Asia and was used for centuries in the making traditional Korean paper (Hanji) , Japan (Washi) or Java.

- 1.Gou Pi or Mulberry Spanish

- 2. fibers constituting the branches of Gou Pi

- 3. Cut the bark into thin strips stringy

- 4. Cut the bark into thin strips stringy

- 5. Cut the bark into thin strips stringy

Is used for making paper from the inner bark of the tree, high fiber, which is obtained by peeling bark in the direction of length with the aid of a blade until kinds of ribbons white and stringy.

Cut by Dai in the forest, where it grows in its wild form, this tree has not been cultivated by them today becoming increasingly scarce and expensive. Except for a few villages that continue to produce paper from the tree, Yunnan Dai usually buy the tapes Gou Pi dry, often from Burma.

The dry material is then rinsed in the river where they will remain overnight in running water.

- 1.Gou Pi Tapes dry as sold on the market

- 2. Tapes Gou Pi sec

- 3. Tapes Gou Pi after cooking

- 4. Removing Gou Pi after cooking ash

- 5. Removing Gou Pi after cooking in the ashes

In the morning these strips of wood fibers are removed from the river and then mixed with ash for Rendes basic white. The best for this is ash ash black walnut provides a more intense white.

Are thus alternating layers Gou Pi ash layers in similar proportions. This preparation is then heated in a large iron wok can hold twenty kilograms. Covered with a hemp fabrics, we let simmer between six and seven hours, during which we will need to add a little ash, while the wood will soften and will lose its original consistency.

Future paper pulp, which has so far the pace of dialogue is brownish flexible tape is then transported to the river to be washed. First roughly washed to remove crumbs from the shaft. Then, wash the "ribbon" one by one, and using a spatula or knife bamboo and removing the remaining ash.

And washed and the waterlogged Guo Pi now has the appearance of long ribbons white, soft and stringy and is ready to be hammered.

Placed between one and two kilograms of this material on a large flat stone, which will hammer with two heavy wooden mallets. Hammering will last about half an hour, after which we get a fine paste and sweet, consisting of wood fibers separate half. Hammering and carried out without interruption, with a very slow and steady, a mallet striking the batter when the other and its highest point, producing a dull rhythm and burying.

Paper fibers then eventually to separate the water in which they are suspended homogeneously before the formation of the paper sheet itself. These are among the most delicate stages and require a real expertise. Various techniques exist, such as one where each screen is added to the fiber needed to form the sheet:

- 1.Dispersion paper fibers before sheet formation

- 2. Dispersion of paper fibers before sheet formation

- 4. Dispersion paper fibers before sheet formation

- 5. Dispersion of paper fibers before sheet formation

The screen is maintained that the bottom of a shallow pool of water. Is then deposited in the water of a handle of the pulp quantity necessary for the manufacture of a sheet, depending on the size of the latter. Then dispersed fibers in performing different sense of motion with his hands, and tapping the surface, so that the fibers are distributed in the basin evenly. We often prefer a colored background (blue on the photo) to better visualize the fiber suspensions in water. It is also at this time that we inspect the quality of the material, and that it removes all possible unwanted item and has not been removed for washing, such as rocks, dirt, etc..

Another method to a village in Xishuangbanna, implements a much deeper pool:

- 1.Dispersion paper fibers before forming sheets of paper

- 2. Dispersion of paper fibers before forming sheets of paper

- 4. Dispersion paper fibers before forming sheets of paper

- 5. Dispersion of paper fibers before forming sheets of paper

Poured in this case a large amount of pulp in the basin, which is dispersed first briefly hand. The fibers are then dispersed over several minutes using a wooden tool, so that they occupy the entire space of the deep basin.

Then comes the most magical time, the film takes shape before our eyes!

- 1. Appearance of the paper to the surface of the screen

- 3. Appearance of the paper to the surface screen

- 4. Appearance of the paper to the surface of the screen

The framework, in the first method was already in the pool, in the second case is inserted horizontally at a given depth. Result is the same so any method. After some time the setting is very gradually removed from the water vertically. The open weave of the fabric, which will leave the water to escape, will trap the paper fibers in suspension like a net. If the action is controlled, these fibers will be deposited in a thin and uniform layer on the surface of the screen. The frame can then be dried.

In the first method, a new framework will then be inserted at the bottom of the basin, on which we will add enough batter to produce new leaves. In the second method, simply drag a new frame horizontally in the basin to trap enough fiber to form a new sheet without having to add to the dough. We deliver just any airborne fibers few sheets always get a uniform result.

The sheets of paper are then left to dry. It frames up for it in the sun, against a wall or frame against frame. Drying time varies depending on the conditions météorologiquess, and may take a few minutes to a few hours. Care must be taken both to overthrow the other part of the bottom up, to ensure consistency of results.

Some papers are calendered to obtain a more smooth and shiny. To do this and when the paper is half dry, it will drag on several occasions porcelain bowl over the entire surface of the paper with light pressure.

- 1. decolage of the paper dry

- 4. The paper sheet of Dai freshly façonée

- 5. Leaf Dai freshly paper façonée

Once the paper is completely dry, you can remove it from the frame. This is done using a wooden spatula. We slide it to gradually spatula between the sheet and the fabric, making no movement up until the sheet is completely peeled off.

The sheets are then folded by 10 and stacks of 100 sheets sold for beings.

uses of traditional Dai paper

Dai paper is traditionally produced two purposes. The first is naturally pack puerh (Pu Er tea) cakes. The strong presence of Dai puerh (Pu Er tea) producing regions, including the Xishuangabanna where they are the majority, naturally makes this paper a paper of choice for quality cakes, especially before the development of the paper industry.

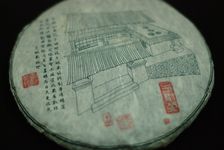

- 1.pancake wrapped paper puerh (Pu Er tea) Dai neutral

- 2. Galette puerh (Pu Er tea) packed Dai printed paper

- 3. Galette puerh (Pu Er tea) packed paper Dai

- 4. Over-the packaging using Dai paper

But the paper is still praised today by a number of producers looking for a quality, or wanting to focus on the size traditional style of their products. It is also very popular with enthusiasts and collectors puerh, including on-pack slabs of their collection in order to preserve and protect their packaging, or to replace an old packaging too fragile.

But there are also villages in Dai, a second job this paper. Dai Buddhists are strongly and in particular in Xishuangbanna, religion has an important place in their lives. With their own writing, Dai recorded since ancient times for writing, especially on their religion and beliefs.

- 1.Buddhist Temple in Dai village producing paper

- 2. Dai Woman with a series of written Buddhist Dai packed

- 3. Write Dai Buddhists on handmade paper

- 4. Write on the Dai Buddhists handmade paper

Still today has a great write up in Dai culture, and the monks or Dai villages continue to transcribe the sacred texts by hand, on long strips of paper traditional Dai, which are then folded fan to produce books elongated. In some villages, particularly in the area of Lincang, he must possess individual before his death a complete collection of these write (several hundred pages).

This is the monk of the village, for each person, write by hand for several weeks, this incredible series of characters. Essential to the making of these works, that is, with the production of paper puerh (Pu Er tea) a major motivation for a tradition of papermaking Dai continue ...